SERVICES BOILERS REFURBISHMENT AND OVERHAUL

BOILERS REFURBISHMENT AND OVERHAUL

Boiler service is one of Irontech’s core specialties. Working with us ensures that your industrial boiler is safe, reliable and economical.

Our services extend your boilers life and reduce emergency call outs for breakdowns. Our qualified repair crew can rapidly and efficiently remedy any boiler issues, whether your systems requires minor repairs or emergency generator tube bank replacements.

Irontech’s team of expert boilermakers, certified code welders, and refractory masons assures an outstanding expertise and excellent execution. We understand that any interruption that affects boiler efficiency results in downtime and loss of production. That is why our approach to each repair project is addressed with the highest sense of urgency.

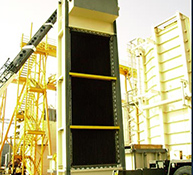

WATER WALL BOILERS

Irontech has extensive experience repairing water tube boilers. Our skilled refractory masons can replace refractory front walls and floors, and our boilermakers can replace tubes and repair casing. Irontech’s water wall boilers services include:

- HP and low-pressure steam drums replacement

- Retube boiler

- Tubes repair

- Fabricate new casing

- Refractory burner and front wall repair

- Refractory floor and seals repair

- National R stamp repairs

- ASME S stamp alterations

- Low water cutoff installation

- Turbine tubes repair

- Hotspots and repair casing

- B31.1 power piping

- Valve installation

- Repair/replace soot blower valves and elements

FIRE WALL BOILERS

Irontech’s fire wall boilers services include:

- Non-destructive testing for cracks in boiler tube sheet

- Boiler door refractory replacement and refurbishment

- Firetube boilers can come in different sizes and configurations

- Boiler door refractory replacement and refurbishment

- Boiler tube replacement and tube repairs

- Rear and front door refractory

- Insulation burner rings refractory

- Tube sheet welding & repair, stay rod (bolt) repair

- Cleaning fireside of tubes

- B31.1 power piping

- New hand hole installation in shell

- Valve installation

- Low water cutoff installation

- Alterations per ASME and NBIC